In the world of garment customisation, heat transfers stand as a versatile and efficient method for bringing your designs to life. Whether you’re a brand looking to create a line of custom merchandise or an artist seeking to translate your creativity onto wearable canvases, understanding heat transfers can empower you to make informed decisions about your projects.

The Basics of Heat Transfer

Heat transfer, in the context of garment customisation, refers to a process where a design is first printed on a non-textile surface, such as vinyl, and then transferred onto a garment using a commercial heat press. This method is particularly popular due to its quick setup and process, making it ideal for personalising the same garment multiple times with different designs.

Most of us are familiar with the jerseys of a sports team. Each player requires a unique number and name, yet the overall design remains consistent across all jerseys. Heat transfer is the perfect solution for such scenarios, allowing for efficient production without compromising on quality.

Popular Heat Transfer Techniques

Plastisol Transfers

Plastisol transfers are a popular choice in the world of garment customisation, and for good reason. This method involves printing your design onto a special transfer paper, which is then heat pressed onto your chosen garment.

Pros:

- Versatility: Plastisol transfers take the quality of screen printing but add the flexibility to print on a wider range of products such as caps or hard to reach areas like inside the neck of t-shirts.

- Precision: As plastisol transfers are screen printed they have the benefit of being able to be pantone matched giving you that precise control of your designs. They are more vibrant than a digital transfer.

- Durability: Plastisol transfers are known for their durability, with designs that can withstand numerous washes without fading.

Cons:

- Limited Colour Range: Plastisol transfers may not be the best choice for designs with a wide range of colours or gradients.

- Feel: The print can sometimes feel heavy or stiff on the garment.

Brands or creators might choose Plastisol transfers when they require precision in their designs, especially for printing on challenging locations. It’s also a great choice for designs that don’t require a wide colour range but need to be durable.

CAD Cut/ HTV

Computer Aided Design (CAD) heat transfer vinyl (HTV) is another popular method. In this process, your design is converted into an outline on Illustrator, run through a vinyl plotter to reveal the shapes of your design, and then heat pressed onto the garment.

Pros:

- Variety of Finishes: This method offers a variety of finishes, including reflective, fluorescent, and velvet, providing more creative freedom.

- Material Flexibility. HTV works across a huge range of fabrics which traditional methods might struggle with. Such as synthetic made fabrics such as nylon and polyester. This is why vinyl is so commonly used in sportswear /activewear.

- Suitable for Small Orders: This method is cost-effective for small orders or single pieces.

Cons:

- Time-Consuming: The process can be time-consuming, especially for complex or large designs.

- Not Ideal for Large Orders: While great for small orders, it may not be cost-effective or efficient for large quantities.

CAD Cut/HTV is a great choice for brands or creators looking to produce bold, blocky designs, custom names, or simple things. It’s also ideal for small orders or single pieces.

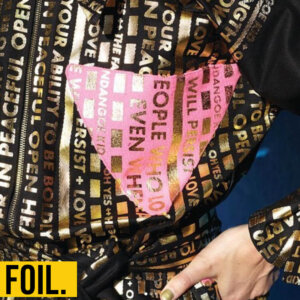

Foil Transfers

Foil transfers offer a unique aesthetic, with two methods available. The first involves screen printing a layer of glue onto the garment, then heat pressing foil on top to seal the design. The second method uses adhesive foil, applied in the same way as CAD cut vinyl.

Pros:

- Unique Aesthetic: Foil transfers provide a shiny, metallic finish that can make your designs stand out.

- Versatility: Foil can be applied to various types of fabrics and garments.

Cons:

- Durability: Foil transfers may not be as durable as other methods, and the foil can start to fade or chip after several washes.

- Complexity: The process can be more complex and time-consuming than other methods.

Foil transfers are an excellent choice for brands or creators looking to create designs with a unique, eye-catching aesthetic. However, they should be mindful of the durability and complexity of the process.

The Power of Heat Transfers in Garment Customisation

Heat transfers offer a world of possibilities for brands and creators. They allow for a high degree of personalisation, are suitable for a range of materials and garment types, and can produce a variety of finishes to suit your design needs.

Whether you’re creating merchandise for a band, launching a fashion line, or producing uniforms for a sports team, heat transfers can provide the quality and versatility you need.

Remember, the key to successful garment customisation lies in understanding the different techniques available and choosing the one that best suits your project. With heat transfers, you have a powerful tool at your disposal.

Conclusion

In the world of garment customisation, heat transfers are a game-changer. They offer versatility, efficiency, and a high degree of personalisation, making them a go-to choice for many brands and creators. By understanding how heat transfers work and the different techniques available, you can make informed decisions about your projects and create custom merchandise that truly stands out.

Remember, at 3rd Rail, we’re dedicated to providing high-quality screen printing and garment customisation services. Whether you’re interested in heat transfers, screen printing, embroidery, or any of our other services, we’re here to help bring your vision to life.

Frequently Asked Questions

What is heat transfer in garment customisation?

Heat transfer is a process where a design is first printed on a non-textile surface, such as vinyl, and then transferred onto a garment using a commercial heat press. It’s a popular method for personalising garments with different designs.

What are the popular heat transfer techniques?

There are several popular heat transfer techniques, including Plastisol transfers, CAD Cut/ HTV, and Foil transfers. Each offers unique advantages and aesthetic finishes, making them suitable for a variety of design needs.

What is a Plastisol transfer?

A Plastisol transfer involves screen printing your design onto a special transfer paper and then heat pressing it onto your chosen garment. It’s particularly useful for Pantone matching colours to keep within brand guidelines.

What is CAD Cut/ HTV?

Computer Aided Design (CAD) heat transfer vinyl (HTV) is a method where your design is converted into an outline on Illustrator, run through a vinyl plotter to reveal the shapes of your design, and then heat pressed onto the garment. This method offers a variety of finishes, including reflective, fluorescent, and flock.

What are Foil transfers?

Foil transfers offer a unique aesthetic, with two methods available. The first involves screen printing a layer of glue onto the garment, then heat pressing foil on top to seal the design. The second method uses adhesive foil, applied in the same way as CAD cut vinyl.

How can heat transfers benefit my brand or creative project?

Heat transfers offer a high degree of flexibility and creative freedom, are suitable for a range of materials and garment types, and can produce a variety of finishes to suit your design needs. Whether you’re creating merchandise for a band, launching a fashion line, or producing uniforms for a sports team, heat transfers can provide the quality and versatility you need.