Welcome to “The Art of Custom T-shirt Printing: Fabrics and Techniques.” In this concise guide, we’ll explore the three predominant garment fabrics: cotton (including its organic variant), polyester, and the cotton-polyester blend. Dive in to understand the synergy between each fabric and various printing techniques, empowering creators to make informed decisions tailored to their brand’s needs.

| Material | Description | Ideal For |

| 1. Cotton / Organic Cotton | Soft, breathable, and durable | Everyday wear |

| 2. Polyester | Lightweight, quick-drying, and wrinkle-resistant | Athletic wear |

| 3. Blend (Cotton-Polyester) | Combines the best of both materials | Versatile use |

1. Cotton / Organic Cotton

Cotton, with its soft, breathable, and durable qualities, remains a timeless pick for custom t-shirts, perfect for daily wear. Organic cotton mirrors these attributes but stands out as an environmentally-conscious option, cultivated without relying on harmful pesticides or fertilisers.

When it comes to Custom T-shirt Printing methods:

- Screen Printing: Cotton works exceptionally well with screen printing. The natural fibres of cotton hold the ink well, allowing for vibrant and durable designs. This is why screen printing is often the go-to method for cotton t-shirts, especially for large orders.

- Direct-to-Garment (DTG): Cotton pairs well with DTG printing, as its fibres readily absorb the ink, producing detailed and vivid designs. However, these prints might not withstand the test of time as effectively as screen prints, particularly after several wash cycles. (DTG Vs Screen Printing)

- Heat Transfer: While cotton can accommodate heat transfer, screen printing or DTG might be preferable choices if you’re aiming for a lasting print with a smoother texture

- Sublimation: Cotton isn’t the best fit for sublimation. This technique demands a polyester-based material since the dye bonds with synthetic fibres, a process not feasible with natural fibres like cotton.

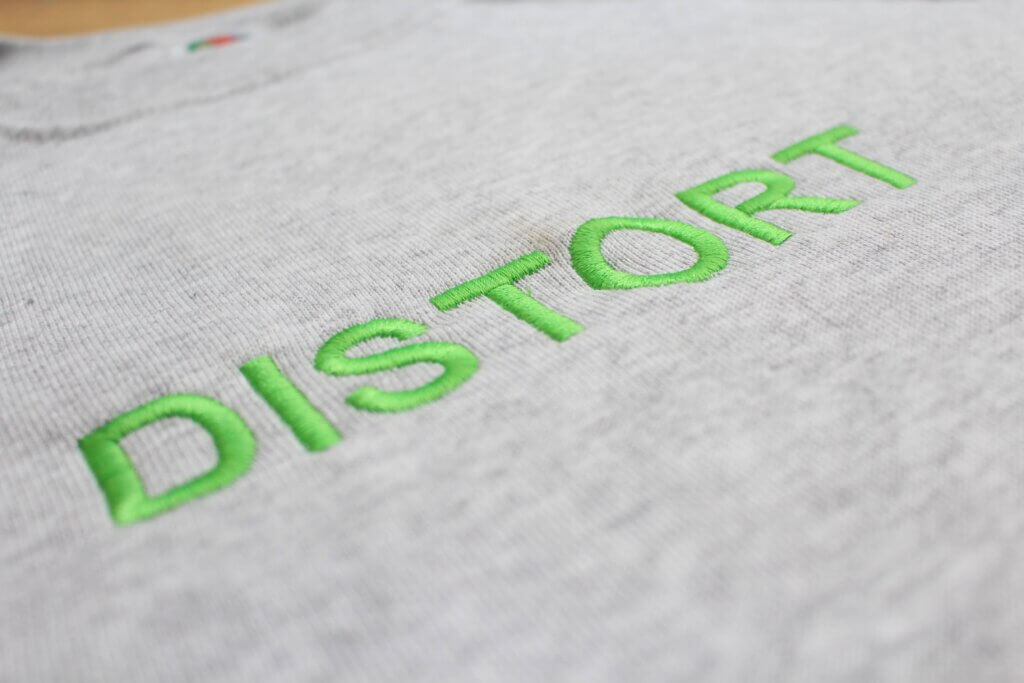

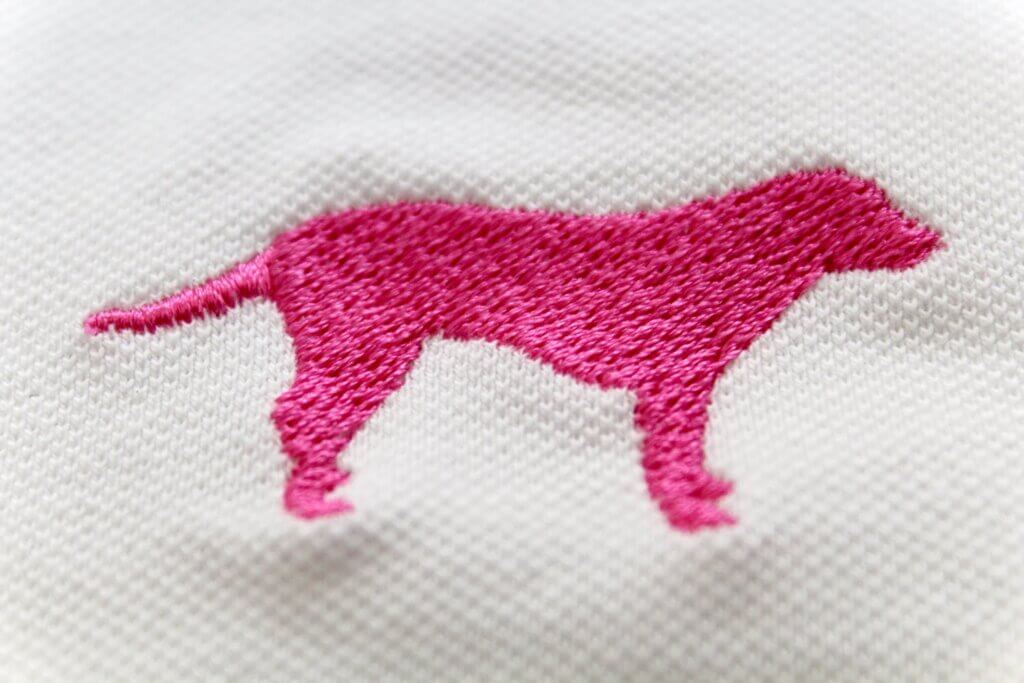

- Embroidery: Cotton’s durability and firmness make it a prime candidate for embroidery. It supports detailed patterns effectively, and its texture ensures the embroidery thread remains securely in place. However, it’s essential to consider the fabric’s weight; lighter cotton t-shirts might not handle embroidery well, leading to potential bunching.

2. Polyester

Polyester, a synthetic fabric, boasts attributes like being lightweight, quick to dry, and resistant to wrinkles, which have made it a favoured choice for sportswear. Yet, its breathability doesn’t match that of cotton, potentially making it less ideal for daily attire.

When it comes to printing methods:

- Screen Printing: Screen printing can be used on polyester, but it can be a bit tricky. Polyester is heat sensitive, and the high temperatures used in screen printing can cause dye migration, where the dye of the polyester fabric bleeds into the screen printing ink. However, with careful temperature control and the right type of ink, screen printing on polyester can still produce good results.

- Direct-to-Garment (DTG): DTG printing is not typically used on polyester. The water-based inks used in DTG printing do not adhere well to polyester fibres, which can result in faded or washed-out prints.

- Heat Transfer: Heat transfer works well on polyester. The heat allows the design to bond well with the synthetic fibres, resulting in vibrant and durable prints. However, as with screen printing, care must be taken to prevent dye migration.

- Sublimation: Polyester is the ideal material for sublimation printing but only if it is white or light coloured. The heat from sublimation turns the solid dye particles into a gas, which bonds with the polyester fibres. This results in vibrant, all-over prints that are durable and won’t crack or peel.

- Embroidery: Polyester is suitable for embroidery. It’s durable and holds its shape well, which is important for maintaining the integrity of embroidered designs. However, the synthetic nature of polyester can sometimes cause issues with thread tension during the embroidery process.

It’s worth noting that environmental concerns surround polyester. Being derived from plastic, its production and degradation contribute to environmental issues. Moreover, there’s growing evidence suggesting that washing polyester garments releases microplastics into waterways, which can eventually reach the oceans.

3. Blend (Cotton-Polyester)

A blend of cotton and polyester combines the best of both materials, offering the comfort of cotton with the durability and wrinkle resistance of polyester.

When it comes to Custom T-shirt Printing methods:

- Screen Printing: Cotton-polyester blends are conducive to screen printing. The combined fibers effectively retain the ink, producing bright and long-lasting designs. This method is favored by brands seeking the softness of cotton complemented by polyester’s resilience. For certain fabric colours and depending on the polyester content, dye blocker bases might be essential to prevent dye migration.

- Direct-to-Garment (DTG): DTG printing is compatible with cotton-polyester blends. The cotton component ensures good adhesion of water-based inks, while the polyester enhances the print’s longevity. However, the print’s intensity might be marginally subdued compared to pure cotton.

- Heat Transfer: While cotton-polyester blends can undergo heat transfer, it might not be the optimal method. Even though the resulting prints can be vivid and intricate, their durability might fall short compared to other techniques.

- Sublimation: Sublimation is typically not recommended for cotton-polyester blends. While it can be done, the dye only bonds with the polyester fibres, leaving the cotton fibres untouched. This results in a faded or vintage look, which may not be desirable for all designs.

- Embroidery: Cotton-polyester blends are excellent for embroidery. The stability of polyester and the softness of cotton make for a sturdy yet comfortable material that can hold intricate embroidered designs well.

| Printing Method | Description | Ideal For |

| 1. Screen Printing | Pantone matched, durable, and cost-effective for large orders | Large batches of custom t-shirts |

| 2. Direct-to-Garment (DTG) | Detailed and no limit on colours, no minimum order | Small batches or one-off prints or designs with lots of colours / gradients |

| 3. Heat Transfer | Highly versatile in terms of design, material and finish. | Synthetic materials like sportswear |

| 4. Sublimation | Vibrant, all-over prints, but only on polyester | Athletic wear or merch giveaways items like bottles, mugs etc |

| 5. Embroidery | Adds texture and a premium feel, but more expensive | High-end fashion or corporate branding |

In conclusion, the choice of material and printing method for your custom t-shirt can greatly influence its look, feel, and durability. Each material, be it cotton, organic cotton, polyester, or a blend, has its unique properties that interact differently with various printing methods like screen printing, DTG, heat transfer, sublimation, and embroidery.

Understanding these interactions is key to making an informed decision that best suits your brand’s needs and the preferences of your target audience. Whether you’re aiming for comfort, durability, eco-friendliness, or a high-end feel, there’s a combination that’s just right for you.

Remember, the best t-shirt isn’t just about the design on the front; it’s also about the quality of the material and the printing method used. By considering all these factors, you can create a custom t-shirt that truly stands out and resonates with your audience.

Stay tuned for part 3 of this series, where we’ll explore how to market and sell your custom t-shirts.

This article is part 2 of a 3-part series on custom t-shirt design brought to you by 3rd Rail. Stay tuned for more insightful content on creating engaging and effective custom merchandise.

FAQs: Custom T-shirt Printing – Fabrics and Techniques

1. What are the primary fabrics used in custom t-shirt printing?

- The main fabrics include cotton (and its organic variant), polyester, and a blend of cotton-polyester.

2. Which fabric is the most eco-friendly?

- Organic cotton is the most eco-friendly option as it’s grown without the use of harmful pesticides or fertilizers.

3. Why might I choose a cotton-polyester blend over pure cotton or polyester?

- A blend offers the comfort of cotton combined with the durability and wrinkle resistance of polyester, making it versatile for various designs and purposes.

4. Can all printing methods be used on any fabric?

- No, certain printing methods are more compatible with specific fabrics. For instance, sublimation works best with polyester, while screen printing is versatile and works well with cotton and blends.

5. How do I prevent my custom t-shirt design from fading?

- The longevity of a print depends on the fabric, printing method, and care of the garment. Always follow washing instructions, and consider choosing printing methods known for durability, like screen printing.

6. Is embroidery suitable for all t-shirt fabrics?

- While embroidery can be applied to most fabrics, it’s essential to consider the fabric’s weight. Lighter materials might not handle embroidery well and could bunch up.

7. How does dye migration occur in screen printing on polyester?

- Dye migration happens when the dye of the polyester fabric bleeds into the screen printing ink due to high temperatures. Using dye blocker bases can help prevent this.

8. Why might the vibrancy of a DTG print on a cotton-polyester blend be reduced compared to 100% cotton?

- The blend’s polyester component doesn’t absorb the water-based inks of DTG as effectively as cotton, which can result in a slightly subdued print.

9. Are there any environmental concerns with polyester t-shirts?

- Yes, polyester is derived from plastic, and its production and degradation can have environmental implications. Additionally, washing polyester garments can release microplastics into waterways.

10. How can I ensure the best print quality for my custom t-shirt design?

- Understand the interaction between your chosen fabric and printing method. Consult with printing professionals and always provide high-resolution designs for optimal results.